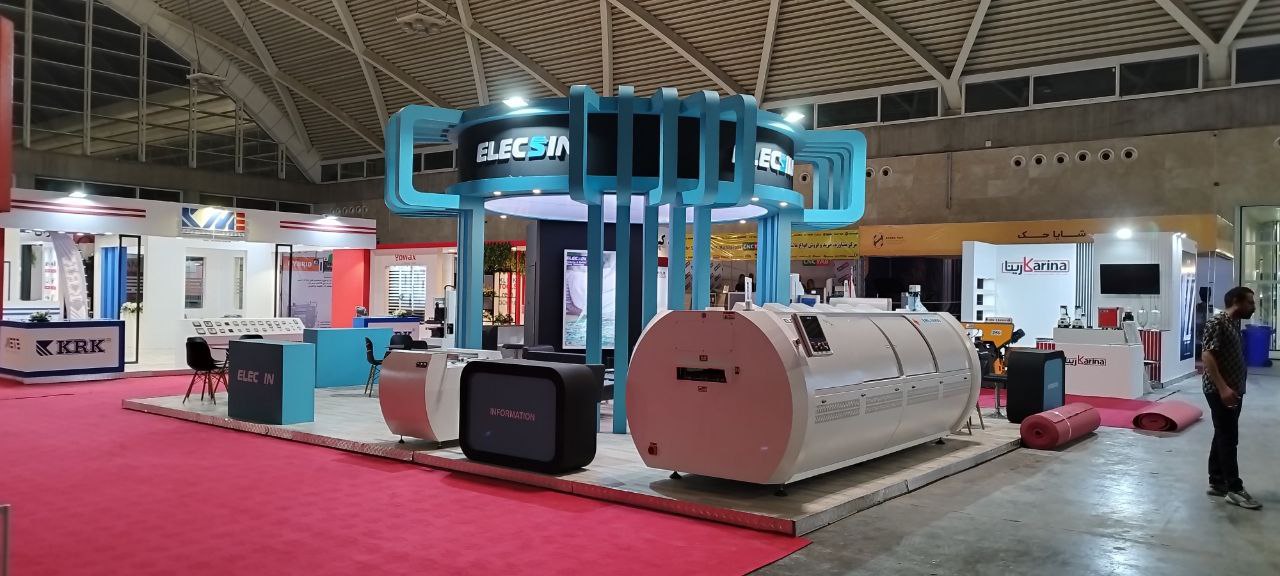

Driving SMT Technology Forward

Innovating the Future of Follower Oven

we teach precision and efficiency through innovation.

Elecsin Innovations specializes in advancing electronics manufacturing through precise SMT solutions, optimizing processes like soldering and component placement with innovative tools such as the "Follower Oven" for reliable and high-performance outputs.

Driving SMT Technology Forward

Innovating the Future of Follower Oven

we teach precision and efficiency through innovation.

At Elecsin Innovations, we are dedicated to advancing precision and efficiency in electronics manufacturing. As a leading provider of SMT solutions, we specialize in designing and implementing cutting-edge technologies that enhance the reliability and performance of electronic components. Our focus is on optimizing processes such as soldering and component placement to ensure high-quality outputs. We leverage innovative tools like the "Follower Oven," which plays a crucial role in reflow soldering after the Pick and Place process, ensuring precise heating and uniform soldering of components.

Optimize Your SMT Line with Follower Ovens

Precision Reflow Soldering for Enhanced Component Quality

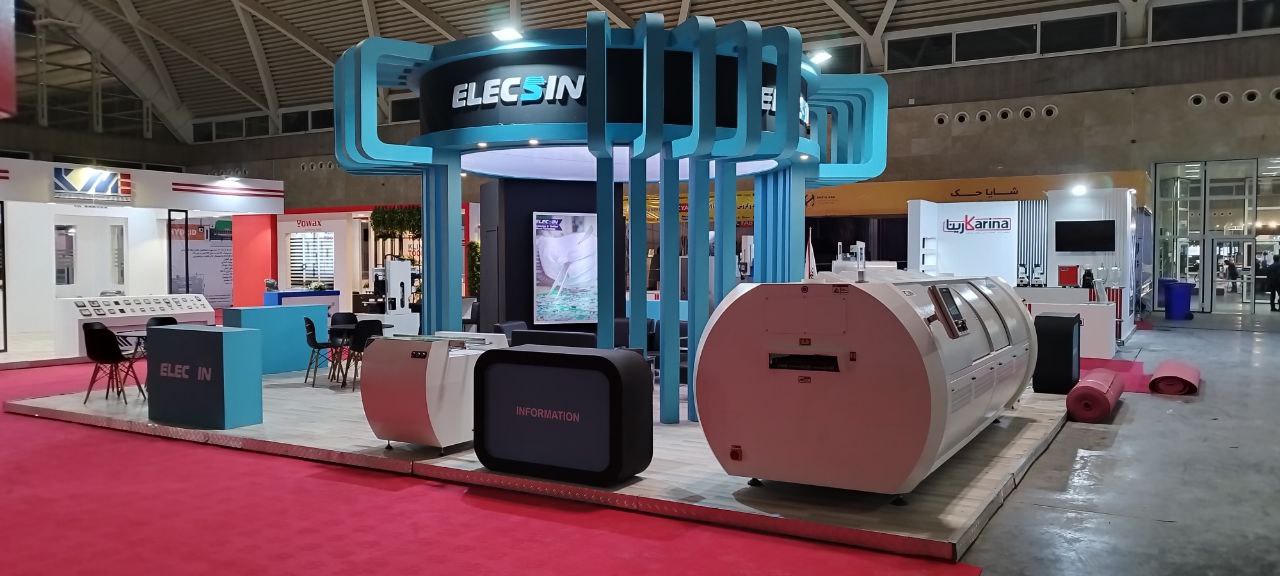

The Follower Oven is a critical component in modern Surface Mount Technology (SMT) production lines, typically positioned after the Pick and Place process. Designed to deliver consistent and uniform heating, it ensures reliable reflow soldering of surface-mount components onto printed circuit boards (PCBs). By maintaining precise temperature profiles, the Follower Oven minimizes defects such as cold solder joints or thermal damage, guaranteeing high-quality outputs.

At Elecsin Solutions, we specialize in integrating advanced Follower Ovens into your manufacturing processes. Our systems are engineered to maximize efficiency, reduce energy consumption, and provide unmatched performance—making them ideal for businesses seeking cost-effective yet high-precision soldering solutions.

Follower Oven Solutions

Our Services

SMT Line Optimization

- Design and Integration of Follower Ovens

- Reflow Soldering Process Enhancement

Component Placement Solutions

- Advanced Pick and Place Technology

- Precision Assembly Techniques

Thermal Management Services

- Temperature Profiling and Calibration

Maintenance and Support

- Regular Equipment Inspections

- Troubleshooting and Repairs

Consulting and Planning

- Customized SMT Workflow Design

- Efficiency Improvement Strategies

Training and Education

- Operator Training Programs

- Best Practices for SMT Operations

Exclusive

High-Speed Pick and Place Machine

Note: Specifications may vary. Contact us for detailed technical data.