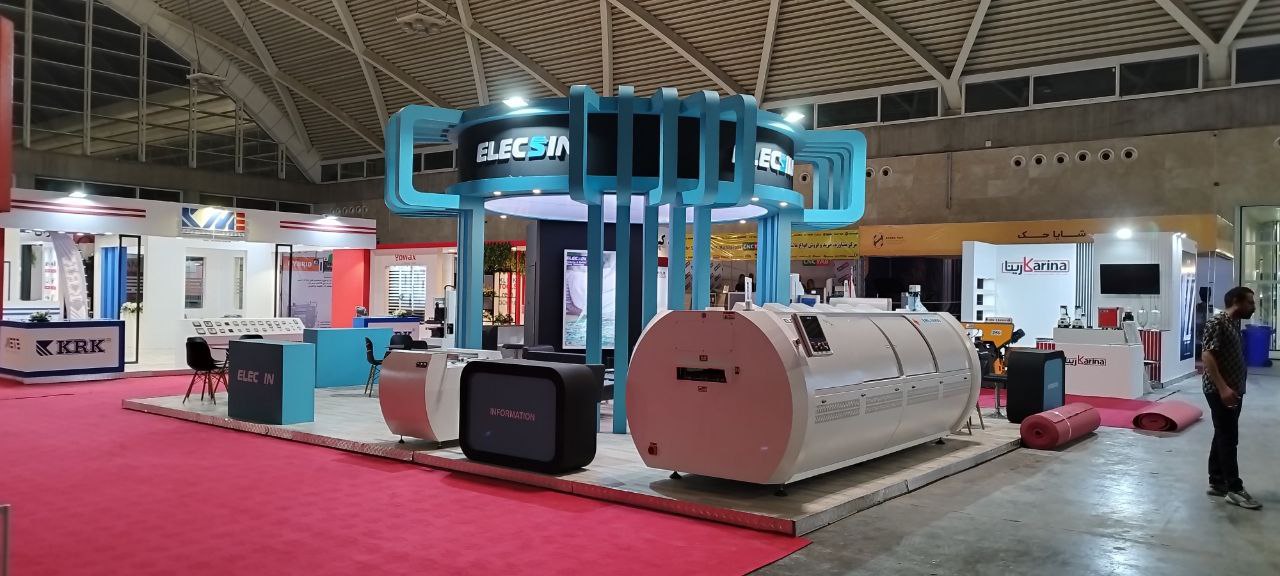

Driving SMT Technology Forward

Revolutionizing Electronics Manufacturing with Advanced Solder Printer Solutions

Driving Precision and Efficiency in Modern Electronics Production

Our advanced Solder Printers automate precise solder paste application on PCBs, ensuring accuracy and consistency. With high-speed capabilities, they reduce errors and boost production efficiency.

Driving SMT Technology Forward

Revolutionizing Electronics Manufacturing with Advanced Solder Printer Solutions

Driving Precision and Efficiency in Modern Electronics Production

Our advanced Solder Printers play a pivotal role in modern electronics manufacturing. These machines automate the precise application of solder paste onto printed circuit boards (PCBs), ensuring unmatched accuracy and consistency. With their sophisticated design and high-speed capabilities, they revolutionize production by reducing human error and significantly increasing throughput.

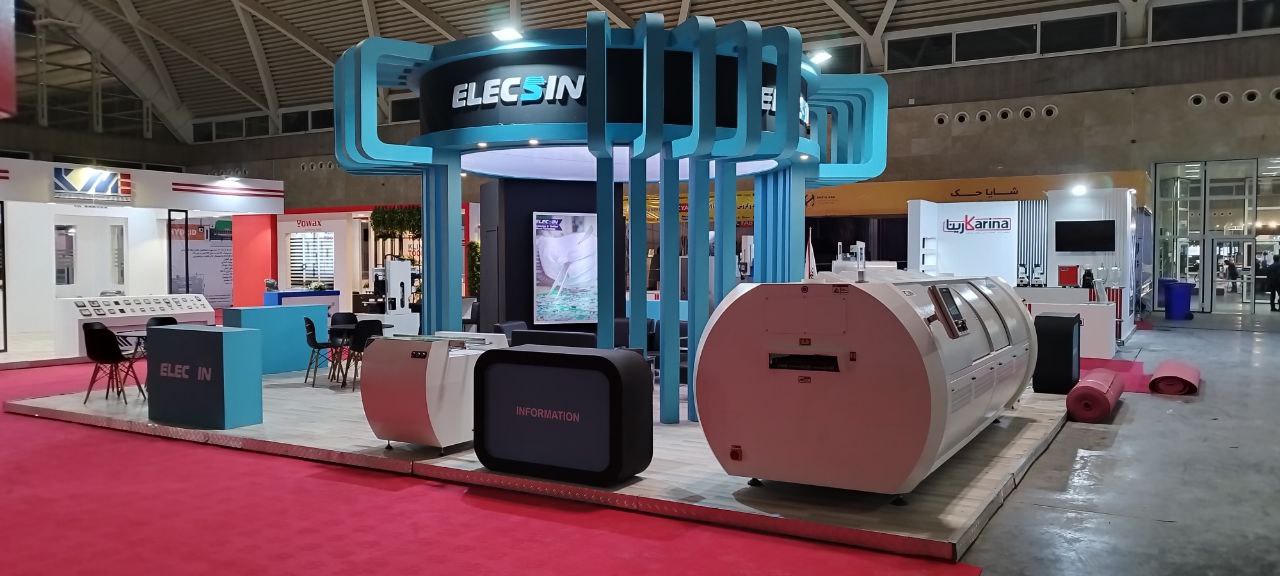

Revolutionize Your SMT Line with Advanced Solder Printer Solutions

Precision Printing for Enhanced Solder Quality

The Importance of Solder Printers in Modern SMT Production:

Solder printers are a critical component in modern Surface Mount Technology (SMT) production lines. Positioned as the backbone of the soldering process, they automate the precise application of solder paste onto printed circuit boards (PCBs). Designed to deliver consistent and accurate printing, they ensure reliable assembly by minimizing defects such as inconsistent solder joints or improper paste application.

How Our Advanced Solder Printers Enhance Efficiency:

At TechFlow Solutions, we specialize in integrating advanced solder printer systems into your manufacturing processes. Our systems are engineered to maximize efficiency, reduce cycle times, and provide unmatched performance—making them ideal for businesses seeking cost-effective yet high-precision assembly solutions. With features like real-time monitoring, adaptive speed control, and seamless integration with other machinery, our solder printers empower you to achieve unparalleled productivity while maintaining the highest standards of quality.

Pick and Place Solutions

Our Services

Enhance the efficiency of your SMT production line by integrating advanced solder printer systems tailored to your specific needs.

Custom design and seamless integration of state-of-the-art solder printers into your existing manufacturing processes.

Optimize reflow soldering operations by ensuring precise and consistent solder paste application.

Ensure accurate and reliable component placement by synchronizing solder printer systems with pick-and-place machines.

Utilize cutting-edge technology for high-speed, precise, and automated solder paste printing.

Implement precision-driven assembly methods to minimize errors and maintain the highest quality standards.

Manage thermal conditions effectively to prevent overheating and ensure optimal performance during solder paste handling.

Conduct detailed temperature profiling and calibration to maintain consistent thermal environments throughout the production line.

Provide expert troubleshooting and repair services to keep your solder printer systems running smoothly.

Schedule routine inspections to identify potential issues before they impact production.

Offer professional consulting and planning services to optimize your conveyor system layout and workflow.

Develop customized workflows that integrate seamlessly with your existing SMT processes.

Implement strategies to enhance throughput, reduce cycle times, and improve overall productivity.

Provide comprehensive training programs for operators and technicians to ensure proficient use of our conveyor systems.

Offer specialized training sessions to maximize operator efficiency and minimize downtime.

Share industry-leading best practices to help you achieve optimal performance in your SMT production environment.

Exclusive

High-Speed Pick and Place Machine

Note: Specifications may vary. Contact us for detailed technical data.